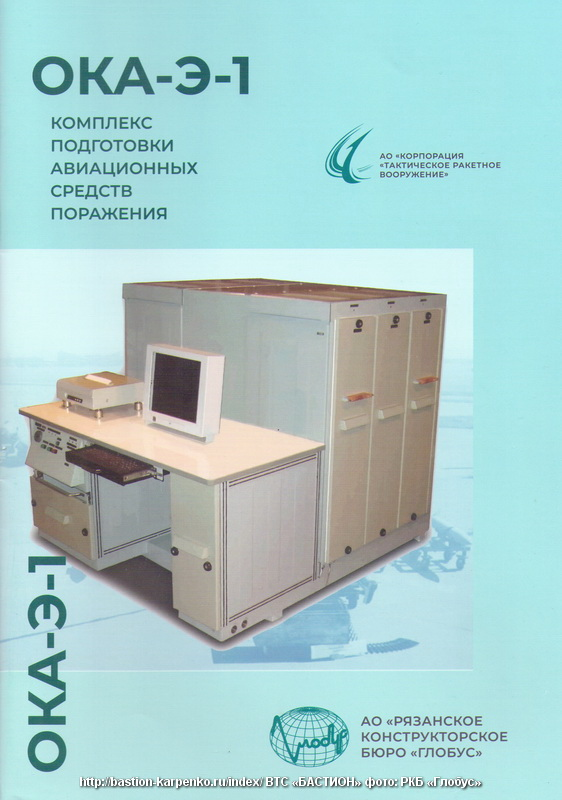

At the International Aviation and Space Salon MAKS-2021 in JSC "Ryazan design bureau "Globus" (a part of JSC "Tactical Rocket Armament Corporation") presented the complex of preparation of aviation means of destruction OKA-E-1.

Basic conception in development of automated systems of technical maintenance and control performed by Globus Design Bureau is an integrated advanced unification, when basic means (basic equipment) are developed and tested ahead of time, and on their basis specific complexes of technical maintenance and control are developed and put into operation.

RSC Globus has created a number of generations of basic means of automated control aggregate complexes (KASAK) and, correspondingly, specific complexes of maintenance and control of weapons and military equipment.

KASAK guarantees creation of practically any maintenance and control complex from unified means.

In RSC Globus a slim design system based on multidimensional unification (basic hardware, software and methods) and optimization of designed systems by efficiency-cost criteria on the basis of multipurpose synthesis theory was created. Over the 60-year practice of designing and implementation of maintenance and control means, a unique library of technical (schematic, design, software) and methodical solutions (control and measurement methods, efficiency estimation, adaptation algorithms, decision-making upon control results, etc.) was developed at the RSC Globus. This library is widely used in the processes of creating specific systems, ensuring their high efficiency.

functional software of the controlled products (working programs of product control).

To ensure the high quality and efficiency of the supplied automated maintenance and control systems the company has created and accumulated a bank of data and normative and technical documentation, which defines the basic provisions for their creation and application:

- basic terms and definitions in the field of automated control;

- classification of automated control systems, control equipment, their structures, etc;

- general requirements to the testability of control objects, the order of relations between developers of automated control systems and control objects, registration of requirements to the control of products;

- basic requirements for the composition, structure, various types of support of automated control systems and their components;

- basic performance indicators and methods of their evaluation;

- design automation systems, covering structural, multi-purpose synthesis of automated control systems;

- the basic principles of the formation of the structure of control systems;

typical methods of control of basic parameters of radioelectronic equipment, formation of stimulating and transformation of controlled signals;

- high-level programming languages, problem-oriented control tasks;

- typical descriptions of the main signals, their characteristics, harmonized with the vocabulary of problem-oriented programming languages;

- standard technology of control, including modes of operation, start and end rules, rationing of human-operator participation in the control process, etc;

- standard requirements to the content and presentation form of information on the control results, on the control object and service personnel;

- typical technology for preparing and changing control programs;

- basic support structure.

All these provisions have been worked out during creation and implementation of specific maintenance and control complexes.

The accumulated experience allows the company to deliver turn-key automated maintenance and control systems with integrated solution of all the necessary issues.

The complex "OKA-E-1" is intended for preparation for use and maintenance of air defence systems, including preparation of air defence systems for use, control of technical condition of air defence systems in the process of their storage and repair.

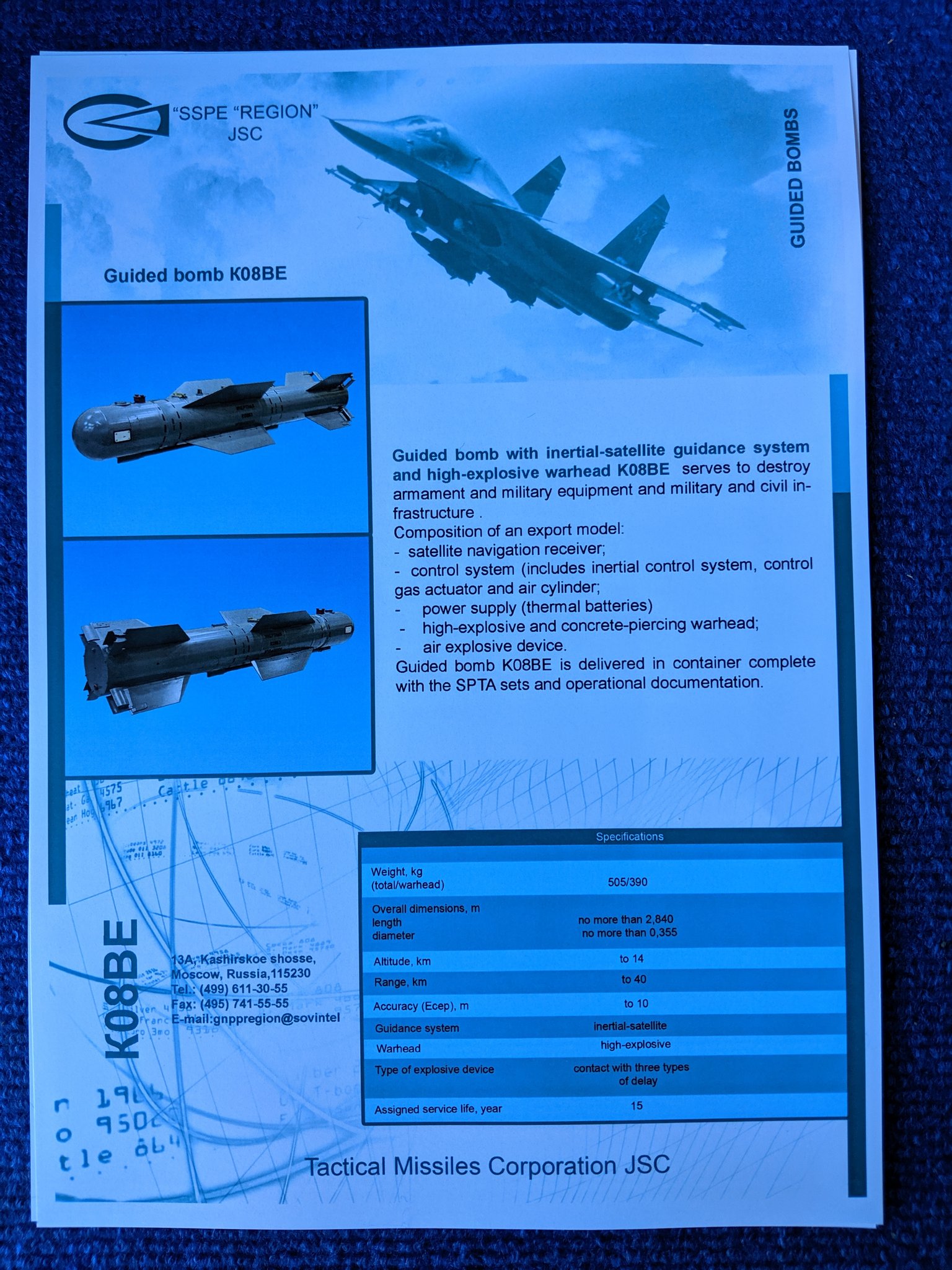

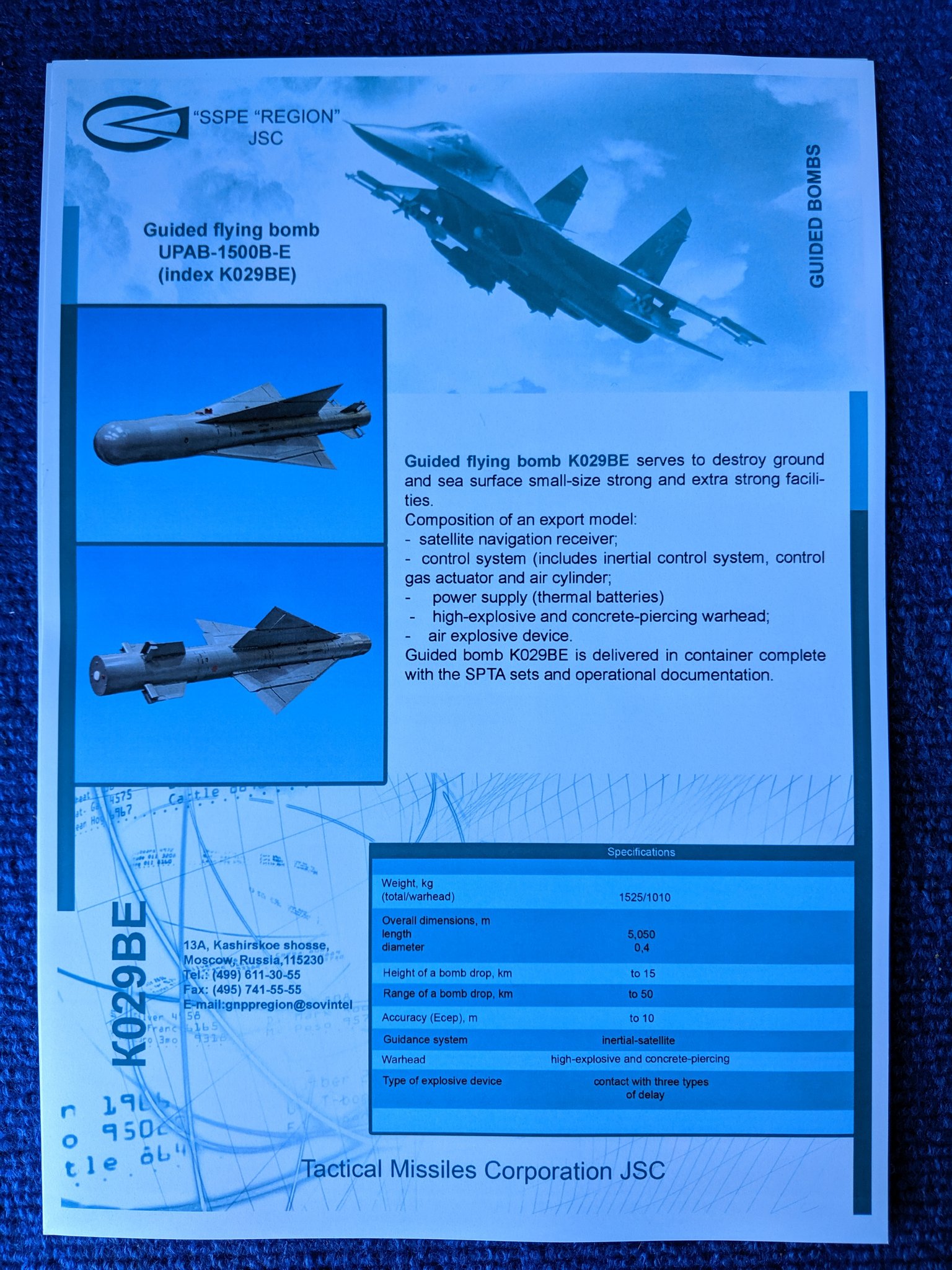

AUSP composition: P-27P1, P-27ER1, P-27T1, P-27ET1, P-73E, P-73L, PBB-AE, PBB-BD, RVV-MD, PBB-SD, X-29T, X-29TE, X-29L, KAB-500Kr, KAB-500 Od, KAB-500S-E, KAB-1500Kr, Kh-59ME, Kh-59MK, Kh-31P (with L111E, L112E, L113E), Kh-31 PK, Kh-31PD, Kh-31A, Kh-35E, Kh-35UE, Kh-38MLE, and other new and their training analogues.

The "OKA-E-1" complex provides:

- Delivery of variants of the complex of redundant versions for any possible combinations of AUSP;

- quick, complete and convenient change-over from one type of the AUSPU to another;

- easy and cheap reconfiguration of versions in case the AUSP composition changes;

- minimization of time and funds expenditures for the "OKA-E-1" complex development in compliance with changes in the whole set of the monitored AHSAS, including those due to prospective AHSAS.

The complex "OKA-E-1" is an up-to-date system with high technical

The complex "OKA-E-1" is a modern system with high technical characteristics of AUSP maintenance.

The complex "OKA-E-1" consists of an automated control system (ACS), means of general

The complex "Oka-E-1" consists of an automated control system (ASC), means of general use and maintenance means.

The ASC is intended to evaluate the technical condition of the AUSP.

General application means and maintenance means are intended for preparation

missiles for control.

ASC consists of all the hardware and software required for the ASCA control, including

including means of electric-pneumatic and nitrogen power supply, program-controlled measuring

converters, generators, shapers, switches of signals and means of communication with the automatic control system.

Complex "OKA-E-1" is operated in the following climatic conditions:

a) reduced ambient operating temperature of minus 10 °С;

b) increased ambient operating temperature of 50 °С:

c) reduced limiting temperature of the environment minus 60 °С;

d) increased ambient limiting temperature of 60 °С;

e) increased relative humidity of 98% at 35 °С;

f) reduced working atmospheric pressure of 6 x 104 Pa (450 mm Hg).

The complex "OKA-E-1" provides determination of technical condition of the controlled object (OK), in accordance with the testability characteristic (QC) - characterizing its fitness for use, with giving an assessment CORRECT or NOT CORRECT.

Determination of the technical condition of the missile under control is performed by:

1) measuring control of parameters with issuing of the evaluation ROD or NOT ROD and indication of deviation of the measured parameter value from the nominal one, expressed in degrees of the tolerance field;

2) performance monitoring with the evaluation of ROD or NOT ROD.

the complex provides:

- formation of power supply voltages of the controlled products, formation of the required stimulating signals, control of analog and digital signals in accordance with the characteristics of testability of QA;

- continuous operation for 8 hours followed by a 1 hour break;

- time of switching from testing of one type of QA to another not more than 30 minutes;

- time of readiness to use not more than 5 minutes after power supply;

- the following light indication at the operator workplace:

a) presence of power supply voltages;

b) indication of an EMERGENCY;

c) failure of the blower;

- input of service data and printout of the control results protocol, which contains

a) date,

b) serial number of the complex,

c) serial number of the control system,

d) the operator's name and additional service information, determined by the operating organization;

Displaying and recording the results of the QA control;

- the following reliability indicators:

a) average MTBF T=1000 hours,

b) average restoration time Tv=2 hours,

c) the nominal service life is not less than 10000 hours within the nominal service life of 10 years;

- the following indicators of reliability of control OK:

a) probability of "false failure" (probability of false rejection of QA) Rl not more than 0,03;

b) probability of "undetected failure" (probability of missing the defective QA) Rno not more than 0.01.

Technical maintenance of the complex is performed by the account that operates the complex.

The complex in transport position is placed in packages.

Self-monitoring efficiency of the complex is not less than 0.95.

The design and configuration of the complex components ensure safety of the personnel in case of

erroneous actions of the personnel.

High maintainability is ensured due to design solutions, effective

self-monitoring.

Power supply - general-purpose industrial mains 3-50 Hz ± 1 Hz, 380 V ±38 V with

of nonlinear distortions not more than 10% or mobile diesel power station.

Power consumed from the power supply network, not more than 8 kW.

Pneumatic power supply - compressor station UKS-400V-P4M with a 1Yu311 (in-house design)

(of our own design), or a source of compressed air with the following parameters: pressure (12-15) MPa, dew-point no higher than

50 "С at pressure of 0.1 MPa, filtration purity (size of solid particles) 10 microns, max.

Air flow rate is not more than 6 m7min.

Nitrogen feeder - nitrogen feeder 1Y312 (of own design) or a source of compressed nitrogen with

parameters: pressure (28-35) MPa, dew-point not higher than minus 65°С at 14.8 MPa, purity

of filtration (particle size) 7 microns or less, absence of drops and vapors of oils, acids,

no oil drops, acids and alkali vapors.

Nitrogen flow rate is not more than 0.017 m7min.

ASC has a trunk-module structure with PC as a main control computer and a two-level system of interfaces.

The modularity is ensured at different structural levels, up to electronic modules of the 1st level.

The first level interface of IEC 625.1 type provides interconnection of the system components with the controlling computer and is interfaced to its internal interface. This level provides the necessary spatial distribution of the system and is implemented by system modules of the adapter (controller) type between the internal interface of the PC and the PSC and the PSC trunk extenders, which solve the issues of matching loads, line lengths, galvanic isolation, etc. The second level interface (inter-module interface - MMI) functions within the limited space of EM2 (block) and provides the interconnection of EM1 modules placed in it with the first level interface through the adapter of the KOP-MMI trunk lines. Subscribers of the second level interface are implemented according to the "device-on-a-board" principle. It provides "transparent" interfacing of the TMC and MMI, so that the means connected to the MMI are controlled in the same way, as those connected directly to the TMC. The only difference is that the MMI subscribers use the system of secondary addresses of the TMC. Application of a sufficiently powerful central computer, flexible system of interfaces, deep level of modularity provide a high level of universality and flexibility of ASC technical solutions, possibility of rational configuration of ASC of various purposes.

The unified basic support structure (BCS), which meets the requirements of the set of state standards for the system of electronic modules, is the basis for constructive design of the automated control systems.

From the standpoint of structural design ASC can be divided into 3 parts: operator workstation (OWB);

- cabinets for housing electronic modules (EM) of different decomposition levels;

- autonomous devices in a typical desktop design.

RMI includes PC and service tools. PC monitor, keyboard and printer are located on the RMO.

Cabinets and devices in the typical construction are fully implemented in BNK, which has the structure:

cell - block - rack (device) - cabinet - complex.

In the rack, EM1 and EM2 are placed in rows. In one row there is one unit or the equivalent

set of EM1 and VIPs

The racks are installed in the cabinets and can be pulled out of them without disturbing the electrical connections. Cabinets are equipped with supply and exhaust ventilation. Racks are set in height (the number of rows), cabinets - in height and width (by the number of racks). The number and size of cabinets

and racks included in them for a particular ASC is determined in accordance with its structure and configuration.

Preparation of the QA for use and its maintenance is carried out in accordance with the QA Operation Manual, and the following works are performed:

- unpacking, removing from the packaging and disassembling the OC;

- loading-unloading works with QA in packing and without packing;

- transportation of QA in packing and without packing on transport-engineering carts or stands;

- testing of QA parameters;

- preservation, packing and packing of testing points.

To perform the above operations four working places are equipped. The first one is placed at the site of unpacking, de-conditioning or in the OK warehouse, and the others are in the working room. Application of sufficiently powerful central computer, flexible system of interfaces, deep level of modularity provide high level of versatility and flexibility of ASC technical solutions, possibility of rational configuration of ASC of different purposes.

The complex has variable composition.

The composition of the complex is determined by the composition of the monitored items, primary

of the monitored items, presence or absence of pneumatic and nitrogen power supply.

Maximum composition of the complex (if there is no industrial network as primary power supply and the items requiring pneumatic and nitrogen supply) is determined by the availability or absence of pneumatic nitrogen supply.

of the complex (without commercial network as the primary power supply and the presence of the articles requiring both pneumatic and nitrogen power supply):

- ASC;

- set of maintenance tools (STO) consisting of:

a) transport cart with straddles;

b) rigging, lifting beams;

c) leveling device;

d) jacks;

e) support;

- diesel power station;

- compressor station;

- air tanker;

- nitrogen refueler;

- truck crane.

Specific configuration of the complex is determined by the type and quantity of serviced AUSP,

set by the customer and specified in the contract for delivery.

Based on "OKA-E-1" complex there are developed versions, defined by the composition of controlled missiles.

The ASC includes:

- PC-based operator workstation;

- a set of modules ensuring formation of the stimulated signals and conversion of the controlled signals of the required nomenclature;

- switching system;

- power supply facilities for the controlled items;

- means of communication with the controlled items;

- ASC functional software (self-monitoring and maintenance programs);

functional software of the controlled items (work programs of controlling the items).

The software of the automated control system is based on the basic software (BPO). The BPO is based on a problem-oriented control system language BASIS and a complete set of software tools, which implement an efficient technology for developing complex software systems of control and monitoring, functioning in real time. The BPO operates in the environment of the modern Russian military operating system Astra Linux.

A set of executable control programs for each ASC is developed:

- a set of executable control programs for a given set of QA;

- a set of executable programs for ASC self-monitoring and maintenance;

- Monitor of control programs, which provides human-operator interaction with the control, self-monitoring and maintenance programs.

The executable control, self-monitoring and maintenance programs are implemented in the framework of the BPO technology and include an executable code and a database, containing a description of the ASK configuration. Separation of the programs into an executable code and a database provides additional opportunities for parametric modification of the programs when changing the ASK configuration. A specialized database generator is available for database development.

The programming system (SP) is adjusted to the ASC configuration. The tuning tool is the built-in database, which describes in a special language: the composition of the devices of a particular ASC, their programmable characteristics, as well as the ASC switching subsystem. To fill and modify the database, the MTP contains a built-in database generator.

For operation of any control, self-monitoring and maintenance program, the ASC forms a typical operating environment in the form of the Control Operational System (COS), which provides for solution of the following main tasks:

- bringing the ASC to its initial state;

- starting and completing the control process (self-monitoring) under the human-operator control;

- a standard dialogue with a human operator at the beginning, end and specific points of the control (self-monitoring) program

- monitoring the ASC equipment status and issuing messages when faults are detected with the organization of the typical control process completion;

- output of the control results protocol

Monitor of control programs is designed to organize dialog interaction of a human operator with the ASC, view the composition of programs and their characteristics, call for execution of control programs, self-monitoring and maintenance, and provides protection against unauthorized access to the equipment.

Monitoring of the technical condition of the QA includes:

- evaluation of each QA parameter under control by the "READY - NOT READY" principle;

- forming of the final estimate of the technical state of QA by the principle "OK OK OK OK OK OK OK OK OK NOT OK";

- continuous monitoring of the emergency parameters with the power supply cut off from the OC at detection of the emergency situation;

- calculation of relative deviations from nominal values of measured parameter values, evaluated quantitatively;

- the following variants of control programs execution:

a) without stopping, irrespective of the results of parameter control, except in case of detection of an emergency situation;

b) with a stop on each parameter, which has received an assessment "NOT READY" with the sign of the possibility of adjustment (the set of conditions of a stop is assigned by a human operator);

c) selective control, when the order of execution of the program sections available for independent from each other implementation is determined by a human-operator.

ASC adopts a method of presenting the results of control of quantitative parameters in the form of deviation of the measured value from the nominal in relative units - gradations (fractions) of the tolerance field. In this case, one number contains the information about the measured value and its position relative to the tolerance field boundaries. The ASC operator, having such data on all parameters, can, without delving into their physical meaning and without additional calculations, assess the level of technical condition of QA, the need to improve it by means of adjusting and adjustment works, and can perform these works without resorting to any other data.

Total number of grades 18: 10 grades (+1, +2, +3, +4, +5, -1, -2, -3, -4, -5) - in the tolerance field, 8 grades (+6, +7, +8, +9, -6, -7, -8, -9) - outside the tolerance field. The tolerance to a parameter may be either equilateral or multilateral. And the number of gradations in the tolerance field does not change.

When documenting the control results for each quantitative parameter, the following are recorded: its conditional number, evaluation ("OK / NOT OK"), deviation in degrees (± 1 ... ± 9), and, in case of self-monitoring, the measured and the limit values of the "NOT OK" evaluation.

The operator interface is "human-operator friendly" and excludes human-operator influence on the control results.

The information-diagnostic troubleshooting system (IDSPN) is a set of

software and methodological tools developed for use in automated control systems

control systems. The main purpose of IDDSS is organization of information support of the troubleshooting process

troubleshooting process in ASC.

The principle of IDSPN functioning is based on the idea of using the results of control objects

control objects for detecting faults in the ASC.

NRSIRPI is a universal software system, oriented to a wide class of

objects of control and includes:

- a specialized database for systematized storage of information on the ASC structure with binding of all signal circuits to the controlled parameters of specific objects of control;

- the program of logical analysis of the control results;

- Dialogue program, which interacts with the user and generates the recommendations for troubleshooting in ASC;

- a program for physical formation of ASC circuits in order to "wire" them and check their serviceability.

Due to the special organization of the database it was possible to achieve a high speed of the control results analysis. This time does not exceed 2-3 seconds for an average complicated ASK.

The application of IDSPN allowed considerably increasing the efficiency of troubleshooting process in ASC, reducing the requirements to the qualification of operating personnel and, as a result, to obtain a significant economic effect.

The use of "OKA-E-1" complex will allow: - provide maintenance of ASCA on the basis of modern automated control means; - provide uniform methods and means of maintenance for all ASCA in service; - simplify the maintenance process, reduce requirements to the number and qualification of maintenance personnel; - provide maintenance of other ASCA in case they enter service with a minimum amount of additional modernization. The complex "OKA-E-1" can also be used for maintenance of other types of armament if it has the appropriate configuration and takes into account the requirements of the object serviced. In particular, for airborne equipment of aircraft, radar facilities, etc. The system is based on modern information technologies with a wide variety of stimulated and monitored signals, high possibilities of data processing, advanced software based on a problem-oriented high-level language for the control tasks. The complex "OKA-E-1" provides an opportunity to order and deliver a configuration, defined by a customer depending on a required range of rockets, stated in the contract for the delivery. At the same time regardless of the missile composition the main characteristics and appearance of the complex practically do not change.