With manned firing trials set to commence in early 2017 ahead of the first Ajax-equipped squadron due to be formed in mid-2019, the British Army is tantalisingly close to fully realising a requirement that can trace its routes through a series of programmes as far back as the early 1980s. IDR examines the development so far

Despite its somewhat troubled past, the solution being procured, the Ajax family of vehicles represents the newest and most advanced addition to the British Army's combat vehicle portfolio and will form a cornerstone of the army's two new strike

brigades, announced in the 2015 Strategic Defence and Security Review (SDSR).

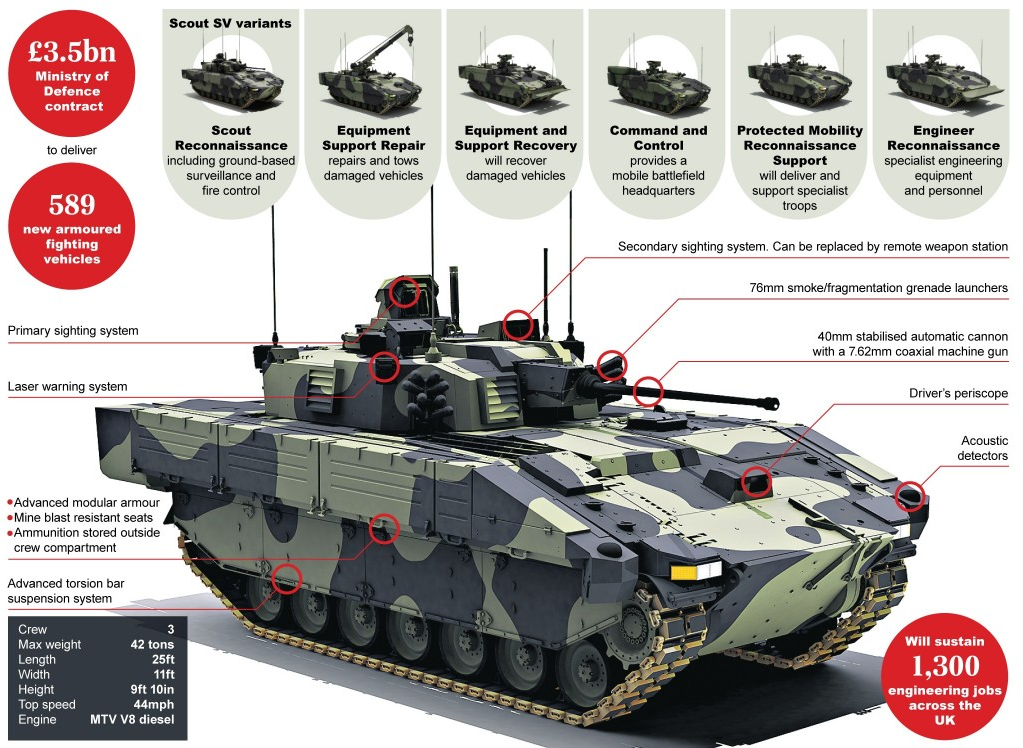

The Ajax programme introduces a family of advanced combat vehicles. (General Dynamics UK)

1650441

The origins of the Ajax programme date back to the 1980s as a series of programmes including the Future Families of Light Armoured Vehicles (FFLAV), Tactical Reconnaissance Armoured Combat Equipment Requirement (TRACER), and Multi-Role Armoured Vehicle (MRAV) sought a replacement to the CVR(T) family of tracked reconnaissance vehicles

The Future Rapid Effects System (FRES) programme emerged from these efforts and sought to procure two classes of vehicle: a tracked armoured reconnaissance 'specialist vehicle' (FRES SV) to replace the CVR(T); and a wheeled 'utility vehicle' (FRES UV) to replace a number of legacy systems including the Saxon armoured personnel carrier (APC), FV432, and some elements of the CVR(T) family. Like its forebears, FRES was not immune from problems, and in 2009, the FRES UV requirement was postponed following the successful selection of General Dynamics UK as the provisional preferred bidder. It was assessed that equipment procured under urgent operational requirement (UOR) arrangements for operations in Afghanistan, including the Ridgeback and Mastiff platforms, would for the time being fulfil the FRES UV capability gap. This enabled the programme to be brought forward and it was subsequently announced that FRES SV would be procured in a single programme utilising a common based platform (CBP) solution.

This version of FRES SV was grander in scope than the Ajax family that has been procured, with between 1,200 and 1,300 vehicles planned in 16 variants. Notable omissions include an anti-tank mine layer; a vehicle-mounted anti-tank guided missile (ATGM) platform, a ground-based surveillance (including ground-based radar) vehicle, unit aid post and battlefield ambulance vehicles, and a direct-fire vehicle armed with a 120 mm smoothbore main gun. Although some of these capabilities are still to be acquired via other projects, including a protected battlefield ambulance and bridging vehicle under the Armoured Battlefield Support Vehicles (ABSV) programme, some of the more notable capability-enhancing variants such as the direct-fire and ATGM vehicles have no planned replacement.

Despite these problems, Ajax could have fared far worse. At the same time that the FRES programme has been running, the United States has also been seeking a new armoured fighting vehicle (AFV) through a series of failed programmes. The Future Combat System (FCS) that ran from 2003 to 2009 was a bold effort to modernise the entire US land inventory with a range of manned and unmanned platforms, including a reconnaissance and surveillance vehicle (RSV). FCS was significantly restructured, and in effect largely cancelled in April 2009. The manned ground vehicle element continued under the new guise of the ground combat vehicle (GCV), a platform that the US Army said would be "relevant across the entire spectrum of army operations and would incorporate combat lessons from Iraq and Afghanistan." GCV would also fail to reach a successful conclusion, and despite two vendors being awarded a total of over USD889.6 million in technology development (TD) contracts, the programme was terminated in the fiscal year 2015 US Presidential Budget Request citing budgetary cutbacks.

Significant concerns had been raised beyond cost reasons, however, with the platforms having rapidly gained in size and weight over the development process, at the time of cancellation, this was anticipated to weigh as much as 80 tonnes and to be physically larger than an M1 tank in some configurations. In addition, a Congressional Budget Office (CBO) report into the GCV programme and potential alternatives to a newbuild approach found that although no alternative completely met the unique GCV requirement, options including the German Puma and Israeli Namer had a number of strengths that suggested cracks in the GCV plan. GCV's successor, the Future Fighting Vehicle (FFV), has seen early developmental contracts awarded, but at present there is no clearly defined timeline for the acquisition of this capability with nothing likely to be procured before 2035 at best.

Following the award to General Dynamics Land Systems UK (GDLS-UK) in September 2014 of a GBP3.5 billion (USD4.3 billion) contract for 589 Ajax (then the SCOUT Specialist Vehicle: [SV]) vehicles in six variants, there was a flurry of subcontract awards as suppliers were signed up to the project. This included GBP130 million to Rheinmetall for the production of turret shells,called

the Turret Structure and Weapons Mount (TSWM); GBP125 million to Thales for sighting systems and ancillary equipment including the ORION primary sight, local situational awareness cameras, gunnery sights, and DNGS-T3 Stabilised Day/Night Gunnery Sight; GBP27 million to Meggitt for ammunition handling systems, and more than GBP200 million in other contracts to suppliers including Curtiss-Wright, Esterline, GKN Aerospace, Kent periscopes, Kongsberg, Marshall Aerospace and Defence, Over Oxley Group, Raytheon, Saab, Smiths Detection, ViaSat, Vitavox, Williams F1, and XPI Simulation.

An Ajax variant and Ares variant recently completed early trials, including amphibious, live firing, and automotive testing. The remaining Ajax prototypes have entered preliminary trials and will also undertake an extensive testing schedule. Following next year's manned firing trials, all variants of the Ajax are to undertake further automotive and cold weather trials, power system testing, and assessments of its extensive ISTAR systems. When production commences, the first 100 vehicles will be assembled at the facilities of General Dynamics European Land Systems Santa Bárbara Sistemas in Spain. The remaining 489 vehicles will be assembled at the recently commissioned GDLS-UK AFV Assembly, Integration, and Testing facility in Merthyr Tydfil, south Wales. This facility will be fully operational in the second half of 2017, with production running through to 2024.

The Ajax family builds on technology and systems developed for the ASCOD 2 (Austrian Spanish Cooperation Development) infantry fighting vehicle (IFV) - itself based on the ASCOD - which entered service in 2002.

When it enters service the Ajax family will comprise six core variants, with some of these fulfilling multiple roles previously listed as distinct variants of the SCOUT SV programme.

The baseline and most numerous version of the vehicle, with a total of 245 units to be procured, will be Ajax, which somewhat confusingly shares its name with the overall vehicle family. Ajax as a variant will fulfil the SCOUT SV's Reconnaissance and Strike (198 vehicles), Joint Fires Control (23 vehicles), and Ground Based Surveillance (24 vehicles) roles, and is the sole variant to mount the Lockheed Martin UK-manufactured turret. The latter two variants will have a lower main weapon ammunition capacity, replaced with demountable equipment and additional personnel for the specialised roles they will perform.

The next most numerous variant will be Athena, formerly the Protected Mobility Reconnaissance Support - Command and Control, with 124 vehicles to be procured. Athena is based on the Ares variant and will provide a C2 capability to Ajax-equipped formations. It will be operated by a crew of five, comprising two vehicle crew and three C2 operators, a staff officer and two signallers. In addition to a bespoke C2 mission fit, the vehicle carries a Watchkeeper UAV control system.

Some 93 Ares, formerly the Protected Mobility Reconnaissance Support, variants will be procured, which will fulfil the legacy roles of Formation Reconnaissance Overwatch (34 vehicles) and Armoured Personnel Carrier (59 vehicles). Ares is essentially the baseline version of Ajax, fulfilling an APC capability without any significant modifications for additional equipment or weapon systems. It has a crew of two with space for four dismounts and is armed with the same remote weapon station (RWS) found on all Ajax platforms.

Three variants will provide a combat support and engineering capability, with 51 Argus, 50 Apollo, and 38 Atlas, formerly the Protected Mobility Reconnaissance Support - Engineering Reconnaissance; Protected Mobility Reconnaissance Support - Engineering Repair; and Protected Mobility Reconnaissance Support - Engineering Recovery, respectively.

Argus is an engineering reconnaissance platform, designed to enable combat engineer units to assess, mark, and work while under armour. Capabilities include gap and slope measurement, route marking, and demolition work, all of which can be accomplished without leaving the vehicle. Apollo is the armoured repair vehicle, and is to operate in collaboration with Atlas to provide a recovery and repair capability. It can tow other Ajax-series vehicles as well as a dedicated high-mobility trailer used to carry subassemblies for repairing vehicles in the field. Its crane can lift the Ajax powerpack, and has the less common ability to 'self-repair', being able to lift its own powerpack out of the engine compartment. Atlas is a relatively basic version of the Ajax family, mounting standard armoured recovery vehicle (ARV) equipment including two winches and an earth anchor.

The Ajax Recce/Strike vehicle is equipped with the Lockheed Martin UK Scout two-man turret. Production of the turret and weapons systems is a collaborative effort, with the primary companies responsible for components and systems being CTA International (CTAI), Curtiss-Wright, Esterline, Kongsberg, Meggitt, Moog, Rheinmetall, Thales, and Ultra Electronics.

Rheinmetall is producing the turret shells for the Ajax programme. (Rheinmetall)

Rheinmetall is responsible for the base steel turret structure, the cannon mounting structure, and weapon integration. The turret structure is based on the Lance Modular Turret System (MTS). CTAI covers the turret's primary armament, the 40 mm Case Telescoped Armament Systems (CTAS) gun, with the ammunition-handling system (AHS) produced by Meggitt Defense Systems. The Turret Drive Servo System (TDSS), a turret aiming and 2-axis stabilisation drive system, is produced by Curtiss-Wright. The main gun is supplemented by a co-axial Heckler & Koch L94A1 7.62 mm chain gun, four banks of four-barrel external grenade launchers supplied by Thales,

and a Kongsberg Protector RWS armed with a 7.62 mm FN MAG-based general-purpose machine gun (GPMG).

Aiming and sighting systems include Esterline's crew-station displays, driver's display, and video-processing unit. Thales produces the two sighting systems and Local Situational Awareness (LSA) system. Communication between and power to the systems within the turret and the base vehicle is via a slip ring produced by Moog.

:Fleet weaponry

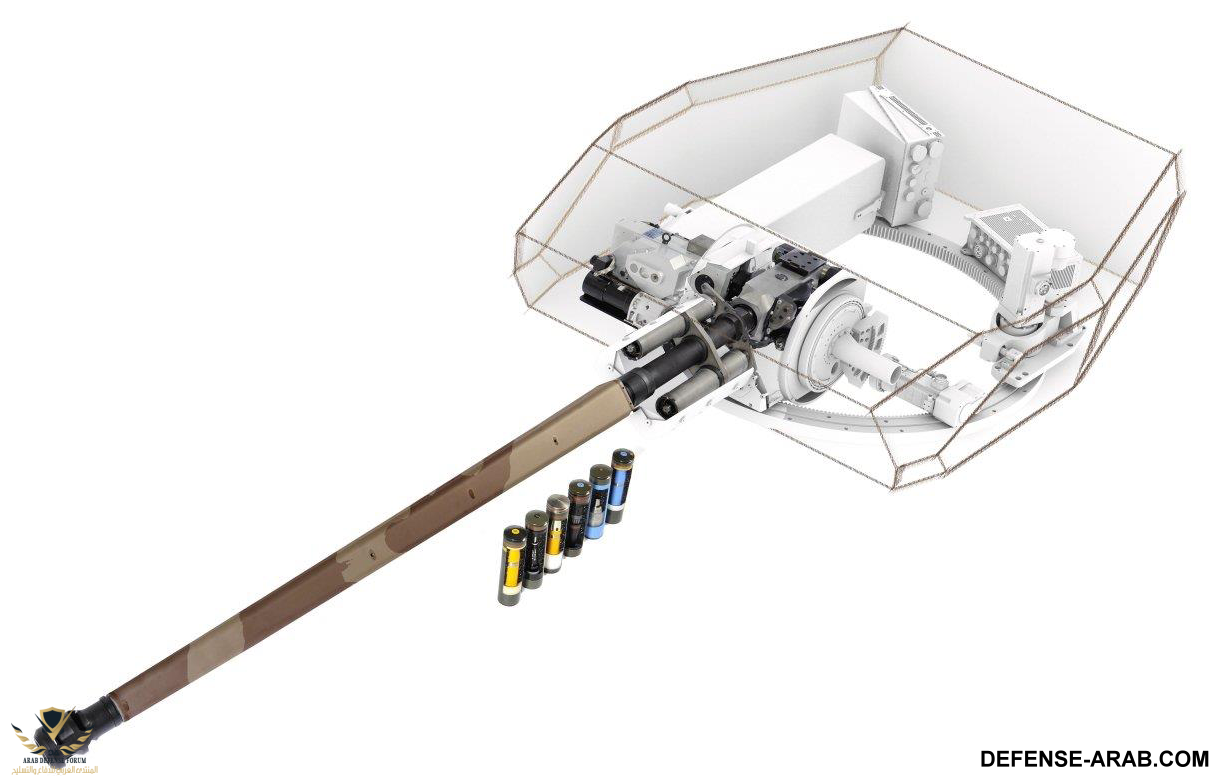

Ajax is armed with the CTAI 40 mm CTAS. The system consists of the 40 Cased Telescoped Cannon (40CTC), an AHS, the CTAS Controller (CTAS-C), the Gun Control Equipment (GCE), the gun mounting (cradle and mantlet), and the 40 mm Case Telescoped Ammunition (CTA) family.

(CTAI)

The CTAI 40 mm Case Telescoped Armament System is the main armament for Ajax.

Guns firing case telescoped ammunition have been under development since the early 1950s, though the current 40 mm CTAS has its origin in work undertaken in France in the mid-1980s and early 1990s by the then GIAT Industries (now Nexter Systems). In 1994, GIAT Industries and Royal Ordnance (now BAE Systems) formed the 50/50 joint venture known as CTAI to develop and market CTA-based weapons.

Initial weapons were of a 45 mm calibre (70 x 305 mm case), as per the previously agreed tripartite (French, UK, US) NATO Standardisation Agreement (STANAG) on CTA cannon. In 1997, the 45 mm calibre was reduced to its current 40 mm calibre (65 x 225 mm case) form with the introduction of the CT2000 gun, the complete system

then known as the 40 mm Cased,

Telescoped Weapon System (CTWS). The name of the system would later change to Cased Telescoped Cannon and Ammunition (CTCA) and finally to its current CTAS form.

The 40CTC is a low-intrusion (sweep volume 74 litres), electronically controlled, electromechanically powered and fired (solenoid-controlled firing mechanism), automatic cannon using a rotating (swing) chamber, and 'push-through' loading system.

Seven natures of percussion-primed ammunition are slated for the Case Telescoped Armament System. (BAE Systems Land and Armaments)

Twin recoil springs are attached near the rear and at an angle on opposing sides of the 2.8 m (70-calibre length) barrel and to the front of the gun cradle. The springs control rearwards and forwards motion of recoiling components of the gun (barrel and housing) against the elevatable cradle. The barrel of the current version of the cannon is fitted with a thermal sleeve. This is attached to a shroud (mantlet) that covers the recoil system and is attached to the cradle.

One or more natures of ammunition is housed within a link-less AHS, which feeds the rounds to what is termed as an 'introductor' situated on the right side of the gun. When required, ammunition natures can be switched in less than 3 seconds.

The CTAS-C is electronic and controls the azimuth and elevation, ballistic computer software, and coincidence control, and can programme certain natures of ammunition. Firing modes include single shot, burst, and automatic fire up to 180 rds/min.

In operation and under control of the CTAS-C, rounds of the required nature are fed from the AHS to the introductor. The chamber is rotated 90° to align with the introductor system and a round is pushed into the chamber. The chamber is rotated 90° again, aligns with the bore axis, and the cartridge is fired. The firing forces (peak 110 kN) cause the 230 kg recoiling components to move nominally 42 mm to the rear, recoil system. The chamber is then rotated 90° again and a new round chambered, this pushing the earlier round out. The firing process is then repeated at the firing rate set by the CTAS-C.

Platform conformity

Described as the future eyes and ears of the British Army, the Ajax variant uses a range of technologies to provide a deployable all-weather ISTAR platform.

Speaking at the SMI Group Future Armoured Vehicles Situation Awareness conference in March 2016, Lieutenant Colonel Mark Cornell, requirements manager for Battlefield and Tactical CIS Delivery Team at the UK MoD, said that post Operation 'Herrick' the tactical user expected global connectivity, rich data services, and seamless data exchange between platforms, as well as tactical broadband and intuitive easy-to-use equipment.

The Ajax family reflects the MoD's adoption of an information centric approach to C4 modernisation with the platform at the heart of information collection and distribution, allowing rapid data dissemination, exploitation, and presentation.

The Ajax integrated mission system uses open standards and promotes a scalable architecture, implemented to increase flexibility, and interoperability and to save costs during future vehicle upgrades and re-roles.

The build of the Ajax platform conforms to the MoD's Defence Standard 23-09 Generic Vehicle Architecture (GVA), which promotes a common approach to vehicle architecture and mandates standards for vehicle design and implementation. The GVA framework uses agreed open standards that underpin electronic infrastructure standards, human-machine interfaces, platform video standards, power infrastructure standards, mechanical standards, and health usage and monitoring systems.

The Ajax modular open architecture is designed to enable fast innovation cycles in computing, sensors, and electronics allowing design portability, and regular spiral evolutions of capability as new technology becomes available. Ajax is intended to enable rapid vehicle reconfiguration as new operational and asymmetric threats emerge and evolve.

The architecture includes a central databus that provides transport infrastructure for video, audio, communications, and platform services, while the electronic architecture integrates the feeds and outputs from equipment such as sensors, weapon effectors, crew interface displays, communication bearers, and internal/external gateways.

Following the initial contract award, General Dynamics sub-contracted Thales to provide the sighting and LSA systems.

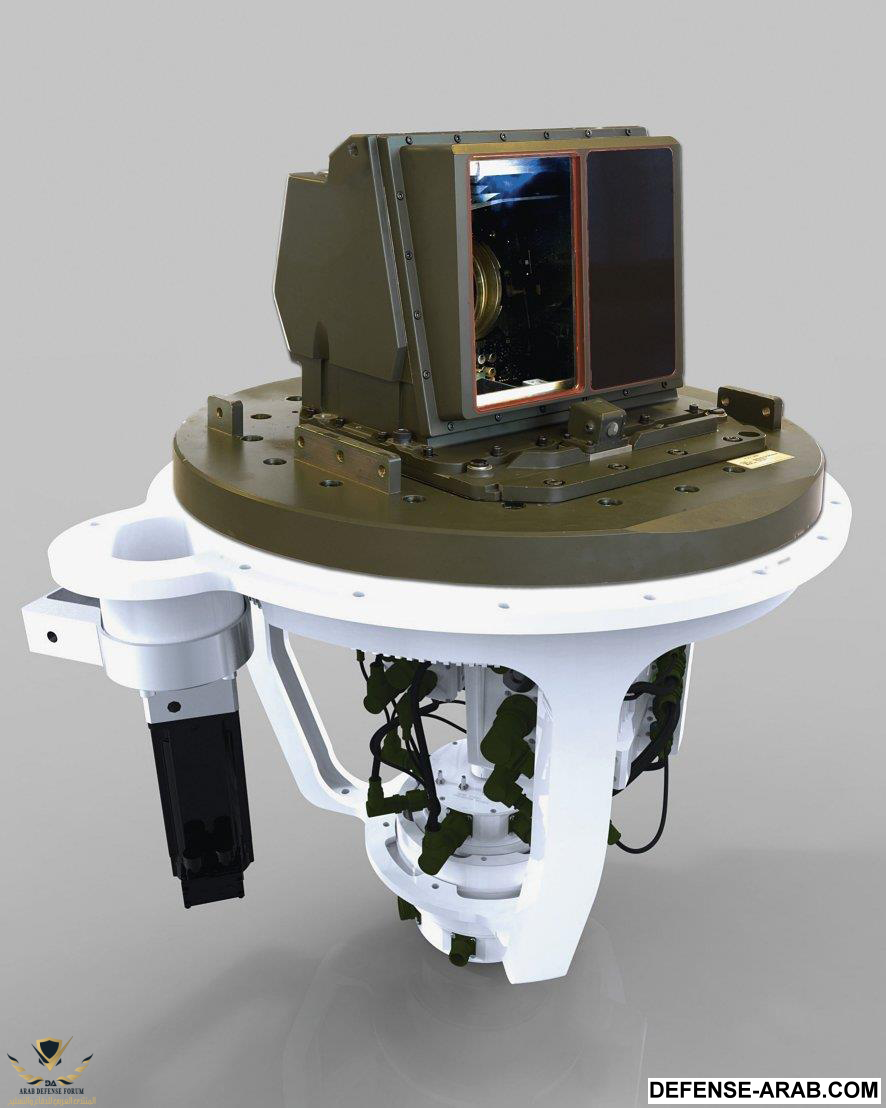

The primary vehicle sighting system fitted to Ajax is the Thales ORION stabilised independent panoramic sighting system that provides the vehicle commander with 360° day/night long-range surveillance and target identification capabilities, independent of the turret orientation. The stabilised system enables on-the-move surveillance and target engagement.

ORION uses the Catherine-MP (Mega-Pixel) thermal imager from Thales Optronics, equipped with a Gen 3 staring focal plane array (FPA). The Catherine-MP is available with a choice of medium-wave infrared (MWIR) or long-wave infrared (LWIR) thermal imagers - the MWIR detector is sensitive in a spectral range of 3-5 μm and features a 15 μm pixel pitch, with a 640 x 512-array format, and the LWIR detector operates in a spectral range of 8-12 μm, and has a 20 μm pixel pitch.

Thales' ORION will be the primary sighting system for the Ajax family. (Thales)

ORION includes an eye-safe laser rangefinder, two high-definition colour TV sensors, and features a gigabit Ethernet (GigE) interface for data sharing and connectivity. The system complies with the UK GVA, and uses open standards for digital video transmission, subsystem connectivity, interoperability, and video transcoding.

The Thales suite includes the DNGST3 dual axis stabilised modular gunnery sighting system. The DNGST3 provides target detection and engagement on-the-move day and night, and incorporates a choice of MWIR/LWIR imager and two HDTV sensors that provide long-range and wide-angle viewing capabilities. The DNGST3 includes an eye-safe laser rangefinder, and features video and GigE interfaces for data exchange with the fire-control system (FCS).

The Thales contract includes the supply of LSA cameras used for 360° day/night close-in surveillance and threat identification using a combination of thermal imagers and day cameras. The Thales LSA uses uncooled thermal imagers to provide the driver and platform crew with an all-round platform view.

Ajax includes vision systems from Wales-based Kent Periscopes. The solution uses unity vision periscopes and a commander's auxiliary sight designed specifically for installation in the Ajax turret. The driver's hatch and hull of the Ajax platform are fitted with two periscopes.

Esterline supplies Codis TX rugged displays used to show information from the platform feeds and sensor inputs. The Codis touchscreen displays are designed for harsh environments and are NVIS-compliant, feature LED backlighting for daylight readability, and include DVI, RGB, USB, and serial interfaces. The products supplied include the Codis TX-335s turret crew station display used to provide gun-control information, system metadata, and logistics information. A Codis TX-321S triple-head driver's display is used to render a 120° view of the route with user feeds from the front, rear, and selectable day or night channel cameras. At the heart of the system is the Codis VPU-101 video processing unit, which is used to process and transcode data from multiple Ajax platform inputs and to distribute it to displays and storage servers.

The Ajax sensor suite includes detectors from Smiths Detection designed to alert the crew of a chemical attack or the existence of persistent chemical agents. The LCD 3.3 requires no calibration or routine maintenance and detects chemical agents including nerve, blood, blister, choking, and a selected library of toxic industrial chemicals. The LCD 3.3 features an auto inlet module (AIM) that enables remote and automatic operation of LCD detectors. The vehicle power supply provides power for the LCD 3.3. The system is suitable for internal and external use, and features certification to environmental standards, MIL-STD-810G, MIL-STD-461F, and MIL-STD-1275.

Ajax features a self-protection suite from Elbit Systems that includes laser warning receivers, missile warning sensors, and an IR jammer. Elbit's laser warning system (E-LAWS) provides the detection, categorisation, and location of laser sources including rangefinders, designators, and IR illuminators. The advertised spectral range covered by the system ranges from 0.5 to 1.6 m. E-LAWS includes a sensor that mounts to the roof of the turret to provide 360° coverage. The survival solution also includes vehicle IR countermeasures (VIRCM). VIRCM is a low-signature system that provides protection against multiple semi-automatic command-to-line-of-sight (SACLOS) missiles.

Multispectral smoke dischargers mounted on the Ajax turret are automatically directed and launched, and create a smoke screen that obscures an attacker's visual and IR line-of-sight view, allowing the platform to use the obscurant as cover for manoeuvre.

Ajax will include MORPHEUS, the next-generation tactical C4 system set to replace Bowman ComBAT (Common Battlefield Application Toolset) Infrastructure and Platform BISA (Battlefield Information Systems Application). MORPHEUS is part of the MoD Architecture Framework (MODAF) developed to support defence planning and change management activities, and seeks to harness commercial developments in mobile communication and computing, and to apply those to the military tactical environment.

MORPHEUS provides an evolvable, modular open architecture that encourages greater use of MOTS and COTS equipment for affordable technology upgrades using a "plug-and-play" or "plug-and-configure" approach. There is an aspiration for MORPHEUS to deliver dismounted situational awareness (DSA) for ground users.

Kongsberg has signed a production contract with General Dynamics for the delivery of the Kongsberg PROTECTOR RWS. The RWS designed for light- and medium-calibre weapons, is

suitable for all platform variants. When fitted to the Ajax variant, it replaces the ORION primary sight.

In July and August 2016, GDLS-UK and Lockheed Martin UK, with support from CTAI, conducted live test firings of the Kongsberg PROTECTOR RWS. The field trial used the turreted Ares variant of the Ajax family and included the firing of the GPMG, heavy machine gun (HMG), grenade machine gun (GMG), and smoke grenade launchers.

The base hull armour of the ASCOD and that afforded by the addition of appliqué panels provides the same level of protection as that given to its turret. The protection of the Ajax, though undeclared, is thought to follow the same trend as its turret, in that it is at least as good as, if not better than the ASCOD. The internal layout of the vehicle (both ASCOD and Ajax) means that the position of the powerpack and transmission at the front and fuel tanks on the sides gives additional protection to some members of the crew from kinetic-energy and shaped charge weapons. Spall liners are also fitted to the ASCOD, as it is assumed Ajax, these reducing the fragment spray cone angle of any penetrations of the armour should they occur.

Imagery of the Ajax has shown it to be equipped with thick removable side armour boxes/panels that, in its base form, run from the hull top, to the top of the skirts. To improve protection, these boxes/panels can be extended to the same profile as the side skirts, so running downwards almost to the height of the wheel axles. It is not known if, in their empty form, they act as appliqué armour, but it is thought to be so. When populated, they are likely to house various armour systems, such as composite armour, spaced armour, multi-perforated armour, NERA, electric armour, or combinations of these. Due to their construction, they are not thought to hold ERA.

Mine protection of the ASCOD and Ajax is unknown, though the former's protection level is stated to be high and hence expected to be at least Level 3 (an 8 kg mine under any portion of the belly or tracks), if not Level 4 (as per Level 3 but a 10 kg mine). IED protection (blast, fragmentation, and EFP) is unknown as the details of the effectors and levels of protection are classified.

A notable survivability innovation on the Ajax platform is the use of a bespoke Saab Barracuda MCS (mobile camouflage system), a system that has seen increasing use with a number of users including Canada, Germany, the Netherlands, and the United Kingdom. While the MCS that will be fitted to Ajax uses the same core technology as that in service elsewhere, it is tailored to the British Army's requirements. "Every operator can customise what requirements they really see as their main focus, so there are differences in configurations between different systems. There are also differences in the generations [of the camouflage system] because there are developments in materials science that we can integrate into our system in order to give much better performance than the generation before. The system can evolve depending on where the technology is going," Niklas Ålund, Saab Barracuda's director of marketing, told IHS Jane's earlier in 2016.

The configuration developed for Ajax has been designed to meet the British Army's doctrine for where the vehicle will be deployed and the threats it believes they will encounter, Ålund said. "The first one to be launched is the woodland configuration, but there are at least two more configurations for the vehicle for other potential theatres," he added.

Ajax will feature Saab Barracuda's mobile camouflage system and was designed for this capability from the outset. (General Dynamics UK)

All rights reserved to

Transported by Ethan

Despite its somewhat troubled past, the solution being procured, the Ajax family of vehicles represents the newest and most advanced addition to the British Army's combat vehicle portfolio and will form a cornerstone of the army's two new strike

brigades, announced in the 2015 Strategic Defence and Security Review (SDSR).

The Ajax programme introduces a family of advanced combat vehicles. (General Dynamics UK)

1650441

The origins of the Ajax programme date back to the 1980s as a series of programmes including the Future Families of Light Armoured Vehicles (FFLAV), Tactical Reconnaissance Armoured Combat Equipment Requirement (TRACER), and Multi-Role Armoured Vehicle (MRAV) sought a replacement to the CVR(T) family of tracked reconnaissance vehicles

The Future Rapid Effects System (FRES) programme emerged from these efforts and sought to procure two classes of vehicle: a tracked armoured reconnaissance 'specialist vehicle' (FRES SV) to replace the CVR(T); and a wheeled 'utility vehicle' (FRES UV) to replace a number of legacy systems including the Saxon armoured personnel carrier (APC), FV432, and some elements of the CVR(T) family. Like its forebears, FRES was not immune from problems, and in 2009, the FRES UV requirement was postponed following the successful selection of General Dynamics UK as the provisional preferred bidder. It was assessed that equipment procured under urgent operational requirement (UOR) arrangements for operations in Afghanistan, including the Ridgeback and Mastiff platforms, would for the time being fulfil the FRES UV capability gap. This enabled the programme to be brought forward and it was subsequently announced that FRES SV would be procured in a single programme utilising a common based platform (CBP) solution.

This version of FRES SV was grander in scope than the Ajax family that has been procured, with between 1,200 and 1,300 vehicles planned in 16 variants. Notable omissions include an anti-tank mine layer; a vehicle-mounted anti-tank guided missile (ATGM) platform, a ground-based surveillance (including ground-based radar) vehicle, unit aid post and battlefield ambulance vehicles, and a direct-fire vehicle armed with a 120 mm smoothbore main gun. Although some of these capabilities are still to be acquired via other projects, including a protected battlefield ambulance and bridging vehicle under the Armoured Battlefield Support Vehicles (ABSV) programme, some of the more notable capability-enhancing variants such as the direct-fire and ATGM vehicles have no planned replacement.

Despite these problems, Ajax could have fared far worse. At the same time that the FRES programme has been running, the United States has also been seeking a new armoured fighting vehicle (AFV) through a series of failed programmes. The Future Combat System (FCS) that ran from 2003 to 2009 was a bold effort to modernise the entire US land inventory with a range of manned and unmanned platforms, including a reconnaissance and surveillance vehicle (RSV). FCS was significantly restructured, and in effect largely cancelled in April 2009. The manned ground vehicle element continued under the new guise of the ground combat vehicle (GCV), a platform that the US Army said would be "relevant across the entire spectrum of army operations and would incorporate combat lessons from Iraq and Afghanistan." GCV would also fail to reach a successful conclusion, and despite two vendors being awarded a total of over USD889.6 million in technology development (TD) contracts, the programme was terminated in the fiscal year 2015 US Presidential Budget Request citing budgetary cutbacks.

Significant concerns had been raised beyond cost reasons, however, with the platforms having rapidly gained in size and weight over the development process, at the time of cancellation, this was anticipated to weigh as much as 80 tonnes and to be physically larger than an M1 tank in some configurations. In addition, a Congressional Budget Office (CBO) report into the GCV programme and potential alternatives to a newbuild approach found that although no alternative completely met the unique GCV requirement, options including the German Puma and Israeli Namer had a number of strengths that suggested cracks in the GCV plan. GCV's successor, the Future Fighting Vehicle (FFV), has seen early developmental contracts awarded, but at present there is no clearly defined timeline for the acquisition of this capability with nothing likely to be procured before 2035 at best.

Following the award to General Dynamics Land Systems UK (GDLS-UK) in September 2014 of a GBP3.5 billion (USD4.3 billion) contract for 589 Ajax (then the SCOUT Specialist Vehicle: [SV]) vehicles in six variants, there was a flurry of subcontract awards as suppliers were signed up to the project. This included GBP130 million to Rheinmetall for the production of turret shells,called

the Turret Structure and Weapons Mount (TSWM); GBP125 million to Thales for sighting systems and ancillary equipment including the ORION primary sight, local situational awareness cameras, gunnery sights, and DNGS-T3 Stabilised Day/Night Gunnery Sight; GBP27 million to Meggitt for ammunition handling systems, and more than GBP200 million in other contracts to suppliers including Curtiss-Wright, Esterline, GKN Aerospace, Kent periscopes, Kongsberg, Marshall Aerospace and Defence, Over Oxley Group, Raytheon, Saab, Smiths Detection, ViaSat, Vitavox, Williams F1, and XPI Simulation.

An Ajax variant and Ares variant recently completed early trials, including amphibious, live firing, and automotive testing. The remaining Ajax prototypes have entered preliminary trials and will also undertake an extensive testing schedule. Following next year's manned firing trials, all variants of the Ajax are to undertake further automotive and cold weather trials, power system testing, and assessments of its extensive ISTAR systems. When production commences, the first 100 vehicles will be assembled at the facilities of General Dynamics European Land Systems Santa Bárbara Sistemas in Spain. The remaining 489 vehicles will be assembled at the recently commissioned GDLS-UK AFV Assembly, Integration, and Testing facility in Merthyr Tydfil, south Wales. This facility will be fully operational in the second half of 2017, with production running through to 2024.

The Ajax family builds on technology and systems developed for the ASCOD 2 (Austrian Spanish Cooperation Development) infantry fighting vehicle (IFV) - itself based on the ASCOD - which entered service in 2002.

When it enters service the Ajax family will comprise six core variants, with some of these fulfilling multiple roles previously listed as distinct variants of the SCOUT SV programme.

The baseline and most numerous version of the vehicle, with a total of 245 units to be procured, will be Ajax, which somewhat confusingly shares its name with the overall vehicle family. Ajax as a variant will fulfil the SCOUT SV's Reconnaissance and Strike (198 vehicles), Joint Fires Control (23 vehicles), and Ground Based Surveillance (24 vehicles) roles, and is the sole variant to mount the Lockheed Martin UK-manufactured turret. The latter two variants will have a lower main weapon ammunition capacity, replaced with demountable equipment and additional personnel for the specialised roles they will perform.

The next most numerous variant will be Athena, formerly the Protected Mobility Reconnaissance Support - Command and Control, with 124 vehicles to be procured. Athena is based on the Ares variant and will provide a C2 capability to Ajax-equipped formations. It will be operated by a crew of five, comprising two vehicle crew and three C2 operators, a staff officer and two signallers. In addition to a bespoke C2 mission fit, the vehicle carries a Watchkeeper UAV control system.

Some 93 Ares, formerly the Protected Mobility Reconnaissance Support, variants will be procured, which will fulfil the legacy roles of Formation Reconnaissance Overwatch (34 vehicles) and Armoured Personnel Carrier (59 vehicles). Ares is essentially the baseline version of Ajax, fulfilling an APC capability without any significant modifications for additional equipment or weapon systems. It has a crew of two with space for four dismounts and is armed with the same remote weapon station (RWS) found on all Ajax platforms.

Three variants will provide a combat support and engineering capability, with 51 Argus, 50 Apollo, and 38 Atlas, formerly the Protected Mobility Reconnaissance Support - Engineering Reconnaissance; Protected Mobility Reconnaissance Support - Engineering Repair; and Protected Mobility Reconnaissance Support - Engineering Recovery, respectively.

Argus is an engineering reconnaissance platform, designed to enable combat engineer units to assess, mark, and work while under armour. Capabilities include gap and slope measurement, route marking, and demolition work, all of which can be accomplished without leaving the vehicle. Apollo is the armoured repair vehicle, and is to operate in collaboration with Atlas to provide a recovery and repair capability. It can tow other Ajax-series vehicles as well as a dedicated high-mobility trailer used to carry subassemblies for repairing vehicles in the field. Its crane can lift the Ajax powerpack, and has the less common ability to 'self-repair', being able to lift its own powerpack out of the engine compartment. Atlas is a relatively basic version of the Ajax family, mounting standard armoured recovery vehicle (ARV) equipment including two winches and an earth anchor.

The Ajax Recce/Strike vehicle is equipped with the Lockheed Martin UK Scout two-man turret. Production of the turret and weapons systems is a collaborative effort, with the primary companies responsible for components and systems being CTA International (CTAI), Curtiss-Wright, Esterline, Kongsberg, Meggitt, Moog, Rheinmetall, Thales, and Ultra Electronics.

Rheinmetall is producing the turret shells for the Ajax programme. (Rheinmetall)

Rheinmetall is responsible for the base steel turret structure, the cannon mounting structure, and weapon integration. The turret structure is based on the Lance Modular Turret System (MTS). CTAI covers the turret's primary armament, the 40 mm Case Telescoped Armament Systems (CTAS) gun, with the ammunition-handling system (AHS) produced by Meggitt Defense Systems. The Turret Drive Servo System (TDSS), a turret aiming and 2-axis stabilisation drive system, is produced by Curtiss-Wright. The main gun is supplemented by a co-axial Heckler & Koch L94A1 7.62 mm chain gun, four banks of four-barrel external grenade launchers supplied by Thales,

and a Kongsberg Protector RWS armed with a 7.62 mm FN MAG-based general-purpose machine gun (GPMG).

Aiming and sighting systems include Esterline's crew-station displays, driver's display, and video-processing unit. Thales produces the two sighting systems and Local Situational Awareness (LSA) system. Communication between and power to the systems within the turret and the base vehicle is via a slip ring produced by Moog.

:Fleet weaponry

Ajax is armed with the CTAI 40 mm CTAS. The system consists of the 40 Cased Telescoped Cannon (40CTC), an AHS, the CTAS Controller (CTAS-C), the Gun Control Equipment (GCE), the gun mounting (cradle and mantlet), and the 40 mm Case Telescoped Ammunition (CTA) family.

(CTAI)

The CTAI 40 mm Case Telescoped Armament System is the main armament for Ajax.

Guns firing case telescoped ammunition have been under development since the early 1950s, though the current 40 mm CTAS has its origin in work undertaken in France in the mid-1980s and early 1990s by the then GIAT Industries (now Nexter Systems). In 1994, GIAT Industries and Royal Ordnance (now BAE Systems) formed the 50/50 joint venture known as CTAI to develop and market CTA-based weapons.

Initial weapons were of a 45 mm calibre (70 x 305 mm case), as per the previously agreed tripartite (French, UK, US) NATO Standardisation Agreement (STANAG) on CTA cannon. In 1997, the 45 mm calibre was reduced to its current 40 mm calibre (65 x 225 mm case) form with the introduction of the CT2000 gun, the complete system

then known as the 40 mm Cased,

Telescoped Weapon System (CTWS). The name of the system would later change to Cased Telescoped Cannon and Ammunition (CTCA) and finally to its current CTAS form.

The 40CTC is a low-intrusion (sweep volume 74 litres), electronically controlled, electromechanically powered and fired (solenoid-controlled firing mechanism), automatic cannon using a rotating (swing) chamber, and 'push-through' loading system.

Seven natures of percussion-primed ammunition are slated for the Case Telescoped Armament System. (BAE Systems Land and Armaments)

Twin recoil springs are attached near the rear and at an angle on opposing sides of the 2.8 m (70-calibre length) barrel and to the front of the gun cradle. The springs control rearwards and forwards motion of recoiling components of the gun (barrel and housing) against the elevatable cradle. The barrel of the current version of the cannon is fitted with a thermal sleeve. This is attached to a shroud (mantlet) that covers the recoil system and is attached to the cradle.

One or more natures of ammunition is housed within a link-less AHS, which feeds the rounds to what is termed as an 'introductor' situated on the right side of the gun. When required, ammunition natures can be switched in less than 3 seconds.

The CTAS-C is electronic and controls the azimuth and elevation, ballistic computer software, and coincidence control, and can programme certain natures of ammunition. Firing modes include single shot, burst, and automatic fire up to 180 rds/min.

In operation and under control of the CTAS-C, rounds of the required nature are fed from the AHS to the introductor. The chamber is rotated 90° to align with the introductor system and a round is pushed into the chamber. The chamber is rotated 90° again, aligns with the bore axis, and the cartridge is fired. The firing forces (peak 110 kN) cause the 230 kg recoiling components to move nominally 42 mm to the rear, recoil system. The chamber is then rotated 90° again and a new round chambered, this pushing the earlier round out. The firing process is then repeated at the firing rate set by the CTAS-C.

Platform conformity

Described as the future eyes and ears of the British Army, the Ajax variant uses a range of technologies to provide a deployable all-weather ISTAR platform.

Speaking at the SMI Group Future Armoured Vehicles Situation Awareness conference in March 2016, Lieutenant Colonel Mark Cornell, requirements manager for Battlefield and Tactical CIS Delivery Team at the UK MoD, said that post Operation 'Herrick' the tactical user expected global connectivity, rich data services, and seamless data exchange between platforms, as well as tactical broadband and intuitive easy-to-use equipment.

The Ajax family reflects the MoD's adoption of an information centric approach to C4 modernisation with the platform at the heart of information collection and distribution, allowing rapid data dissemination, exploitation, and presentation.

The Ajax integrated mission system uses open standards and promotes a scalable architecture, implemented to increase flexibility, and interoperability and to save costs during future vehicle upgrades and re-roles.

The build of the Ajax platform conforms to the MoD's Defence Standard 23-09 Generic Vehicle Architecture (GVA), which promotes a common approach to vehicle architecture and mandates standards for vehicle design and implementation. The GVA framework uses agreed open standards that underpin electronic infrastructure standards, human-machine interfaces, platform video standards, power infrastructure standards, mechanical standards, and health usage and monitoring systems.

The Ajax modular open architecture is designed to enable fast innovation cycles in computing, sensors, and electronics allowing design portability, and regular spiral evolutions of capability as new technology becomes available. Ajax is intended to enable rapid vehicle reconfiguration as new operational and asymmetric threats emerge and evolve.

The architecture includes a central databus that provides transport infrastructure for video, audio, communications, and platform services, while the electronic architecture integrates the feeds and outputs from equipment such as sensors, weapon effectors, crew interface displays, communication bearers, and internal/external gateways.

Following the initial contract award, General Dynamics sub-contracted Thales to provide the sighting and LSA systems.

The primary vehicle sighting system fitted to Ajax is the Thales ORION stabilised independent panoramic sighting system that provides the vehicle commander with 360° day/night long-range surveillance and target identification capabilities, independent of the turret orientation. The stabilised system enables on-the-move surveillance and target engagement.

ORION uses the Catherine-MP (Mega-Pixel) thermal imager from Thales Optronics, equipped with a Gen 3 staring focal plane array (FPA). The Catherine-MP is available with a choice of medium-wave infrared (MWIR) or long-wave infrared (LWIR) thermal imagers - the MWIR detector is sensitive in a spectral range of 3-5 μm and features a 15 μm pixel pitch, with a 640 x 512-array format, and the LWIR detector operates in a spectral range of 8-12 μm, and has a 20 μm pixel pitch.

Thales' ORION will be the primary sighting system for the Ajax family. (Thales)

ORION includes an eye-safe laser rangefinder, two high-definition colour TV sensors, and features a gigabit Ethernet (GigE) interface for data sharing and connectivity. The system complies with the UK GVA, and uses open standards for digital video transmission, subsystem connectivity, interoperability, and video transcoding.

The Thales suite includes the DNGST3 dual axis stabilised modular gunnery sighting system. The DNGST3 provides target detection and engagement on-the-move day and night, and incorporates a choice of MWIR/LWIR imager and two HDTV sensors that provide long-range and wide-angle viewing capabilities. The DNGST3 includes an eye-safe laser rangefinder, and features video and GigE interfaces for data exchange with the fire-control system (FCS).

The Thales contract includes the supply of LSA cameras used for 360° day/night close-in surveillance and threat identification using a combination of thermal imagers and day cameras. The Thales LSA uses uncooled thermal imagers to provide the driver and platform crew with an all-round platform view.

Ajax includes vision systems from Wales-based Kent Periscopes. The solution uses unity vision periscopes and a commander's auxiliary sight designed specifically for installation in the Ajax turret. The driver's hatch and hull of the Ajax platform are fitted with two periscopes.

Esterline supplies Codis TX rugged displays used to show information from the platform feeds and sensor inputs. The Codis touchscreen displays are designed for harsh environments and are NVIS-compliant, feature LED backlighting for daylight readability, and include DVI, RGB, USB, and serial interfaces. The products supplied include the Codis TX-335s turret crew station display used to provide gun-control information, system metadata, and logistics information. A Codis TX-321S triple-head driver's display is used to render a 120° view of the route with user feeds from the front, rear, and selectable day or night channel cameras. At the heart of the system is the Codis VPU-101 video processing unit, which is used to process and transcode data from multiple Ajax platform inputs and to distribute it to displays and storage servers.

The Ajax sensor suite includes detectors from Smiths Detection designed to alert the crew of a chemical attack or the existence of persistent chemical agents. The LCD 3.3 requires no calibration or routine maintenance and detects chemical agents including nerve, blood, blister, choking, and a selected library of toxic industrial chemicals. The LCD 3.3 features an auto inlet module (AIM) that enables remote and automatic operation of LCD detectors. The vehicle power supply provides power for the LCD 3.3. The system is suitable for internal and external use, and features certification to environmental standards, MIL-STD-810G, MIL-STD-461F, and MIL-STD-1275.

Ajax features a self-protection suite from Elbit Systems that includes laser warning receivers, missile warning sensors, and an IR jammer. Elbit's laser warning system (E-LAWS) provides the detection, categorisation, and location of laser sources including rangefinders, designators, and IR illuminators. The advertised spectral range covered by the system ranges from 0.5 to 1.6 m. E-LAWS includes a sensor that mounts to the roof of the turret to provide 360° coverage. The survival solution also includes vehicle IR countermeasures (VIRCM). VIRCM is a low-signature system that provides protection against multiple semi-automatic command-to-line-of-sight (SACLOS) missiles.

Multispectral smoke dischargers mounted on the Ajax turret are automatically directed and launched, and create a smoke screen that obscures an attacker's visual and IR line-of-sight view, allowing the platform to use the obscurant as cover for manoeuvre.

Ajax will include MORPHEUS, the next-generation tactical C4 system set to replace Bowman ComBAT (Common Battlefield Application Toolset) Infrastructure and Platform BISA (Battlefield Information Systems Application). MORPHEUS is part of the MoD Architecture Framework (MODAF) developed to support defence planning and change management activities, and seeks to harness commercial developments in mobile communication and computing, and to apply those to the military tactical environment.

MORPHEUS provides an evolvable, modular open architecture that encourages greater use of MOTS and COTS equipment for affordable technology upgrades using a "plug-and-play" or "plug-and-configure" approach. There is an aspiration for MORPHEUS to deliver dismounted situational awareness (DSA) for ground users.

Kongsberg has signed a production contract with General Dynamics for the delivery of the Kongsberg PROTECTOR RWS. The RWS designed for light- and medium-calibre weapons, is

suitable for all platform variants. When fitted to the Ajax variant, it replaces the ORION primary sight.

In July and August 2016, GDLS-UK and Lockheed Martin UK, with support from CTAI, conducted live test firings of the Kongsberg PROTECTOR RWS. The field trial used the turreted Ares variant of the Ajax family and included the firing of the GPMG, heavy machine gun (HMG), grenade machine gun (GMG), and smoke grenade launchers.

The base hull armour of the ASCOD and that afforded by the addition of appliqué panels provides the same level of protection as that given to its turret. The protection of the Ajax, though undeclared, is thought to follow the same trend as its turret, in that it is at least as good as, if not better than the ASCOD. The internal layout of the vehicle (both ASCOD and Ajax) means that the position of the powerpack and transmission at the front and fuel tanks on the sides gives additional protection to some members of the crew from kinetic-energy and shaped charge weapons. Spall liners are also fitted to the ASCOD, as it is assumed Ajax, these reducing the fragment spray cone angle of any penetrations of the armour should they occur.

Imagery of the Ajax has shown it to be equipped with thick removable side armour boxes/panels that, in its base form, run from the hull top, to the top of the skirts. To improve protection, these boxes/panels can be extended to the same profile as the side skirts, so running downwards almost to the height of the wheel axles. It is not known if, in their empty form, they act as appliqué armour, but it is thought to be so. When populated, they are likely to house various armour systems, such as composite armour, spaced armour, multi-perforated armour, NERA, electric armour, or combinations of these. Due to their construction, they are not thought to hold ERA.

Mine protection of the ASCOD and Ajax is unknown, though the former's protection level is stated to be high and hence expected to be at least Level 3 (an 8 kg mine under any portion of the belly or tracks), if not Level 4 (as per Level 3 but a 10 kg mine). IED protection (blast, fragmentation, and EFP) is unknown as the details of the effectors and levels of protection are classified.

A notable survivability innovation on the Ajax platform is the use of a bespoke Saab Barracuda MCS (mobile camouflage system), a system that has seen increasing use with a number of users including Canada, Germany, the Netherlands, and the United Kingdom. While the MCS that will be fitted to Ajax uses the same core technology as that in service elsewhere, it is tailored to the British Army's requirements. "Every operator can customise what requirements they really see as their main focus, so there are differences in configurations between different systems. There are also differences in the generations [of the camouflage system] because there are developments in materials science that we can integrate into our system in order to give much better performance than the generation before. The system can evolve depending on where the technology is going," Niklas Ålund, Saab Barracuda's director of marketing, told IHS Jane's earlier in 2016.

The configuration developed for Ajax has been designed to meet the British Army's doctrine for where the vehicle will be deployed and the threats it believes they will encounter, Ålund said. "The first one to be launched is the woodland configuration, but there are at least two more configurations for the vehicle for other potential theatres," he added.

Ajax will feature Saab Barracuda's mobile camouflage system and was designed for this capability from the outset. (General Dynamics UK)

ليس لديك تصريح لمشاهدة الرابط، فضلا قم ب تسجيل الدخول او تسجيل

All rights reserved to

ليس لديك تصريح لمشاهدة الرابط، فضلا قم ب تسجيل الدخول او تسجيل

Transported by Ethan